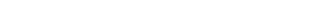

Aluminum alloy pipe clamp manufacturer's analysis of pipe clamp types and detailed explanation of manufacturing process

Different types of pipe clamps are required in the process of pipe fixing. There are many types of pipe clamps, such as plastic pipe clamp, aluminum alloy pipe clamp, U-shaped pipe clamp, flat steel pipe clamp, hydraulic pipe clamp, light pipe clamp, heavy pipe clamp, duplex pipe clamp, etc. different types of pipe clamps are suitable for pipes with different load requirements. However, how are these pipe clamps produced, What is their production process? Let me show you in detail.

1. Plastic pipe clamp: each manufacturer must have a large gram of injection molding machine, stamping machine, CNC machine tool and forging machine equipment. The plastic pipe clamp on the home page is divided into plastic lifting, upper and lower cover plates, screws and nuts. The plastic body is injected according to different models required by customers, and the appearance should be smooth,

The selected plastic particles must be strong in tensile strength, hardness and aging resistance. The upper and lower cover plates are made by punching machine, then they are galvanized, the screws are made by numerical control machine tools, and then galvanized, and then through technical staff to carry out the integrated packaging of pipe clamps.

2. Aluminum alloy pipe clamp: aluminum alloy pipe clamp is basically the same as plastic pipe clamp. The main pipe clamp body is made of aluminum alloy, so the selected equipment is mainly made of aluminum alloy injection machine.

3. U-shaped pipe clamp: the main equipment used is forging press and CNC machine tool equipment. First, select excellent carbon steel, bake it in the oven to a certain extent, press and bend it into U-shaped assembly with forging press, and then galvanize it.

4. Variable steel pipe clamp: the method is the same as that of U-shaped pipe clamp.